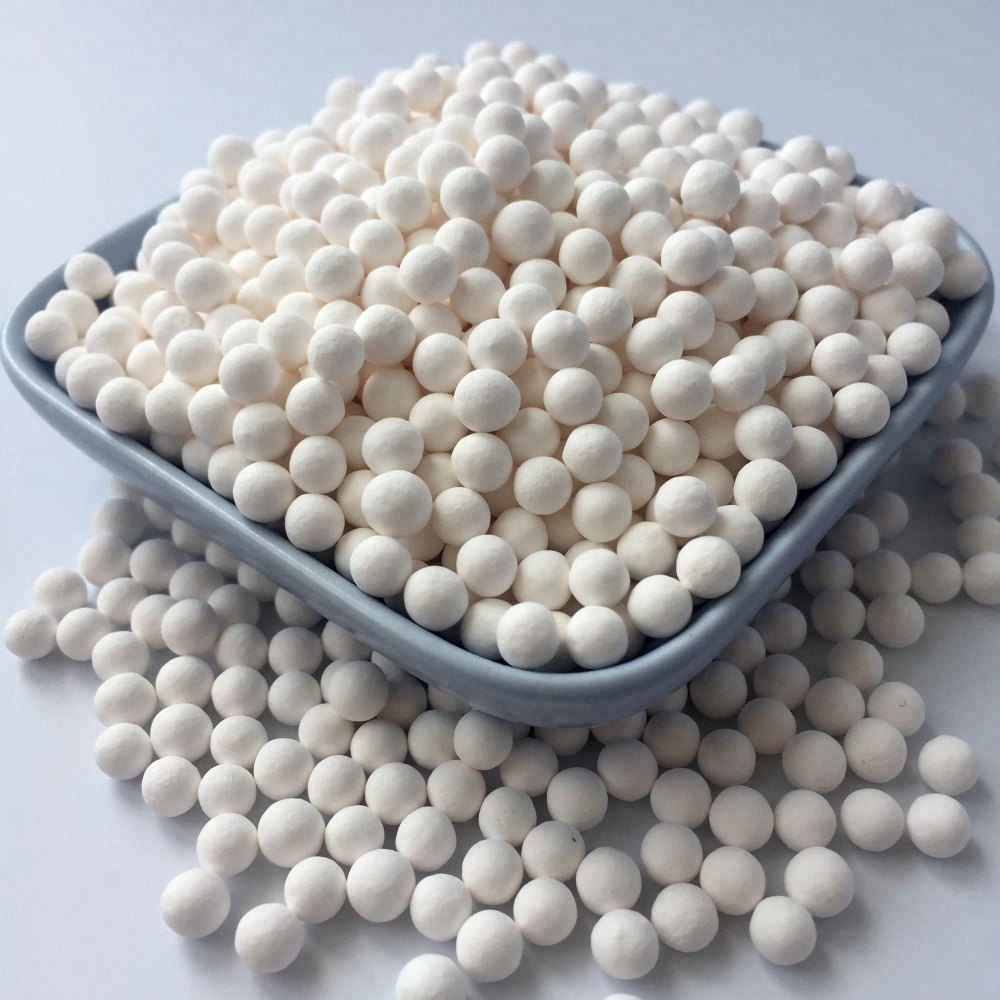

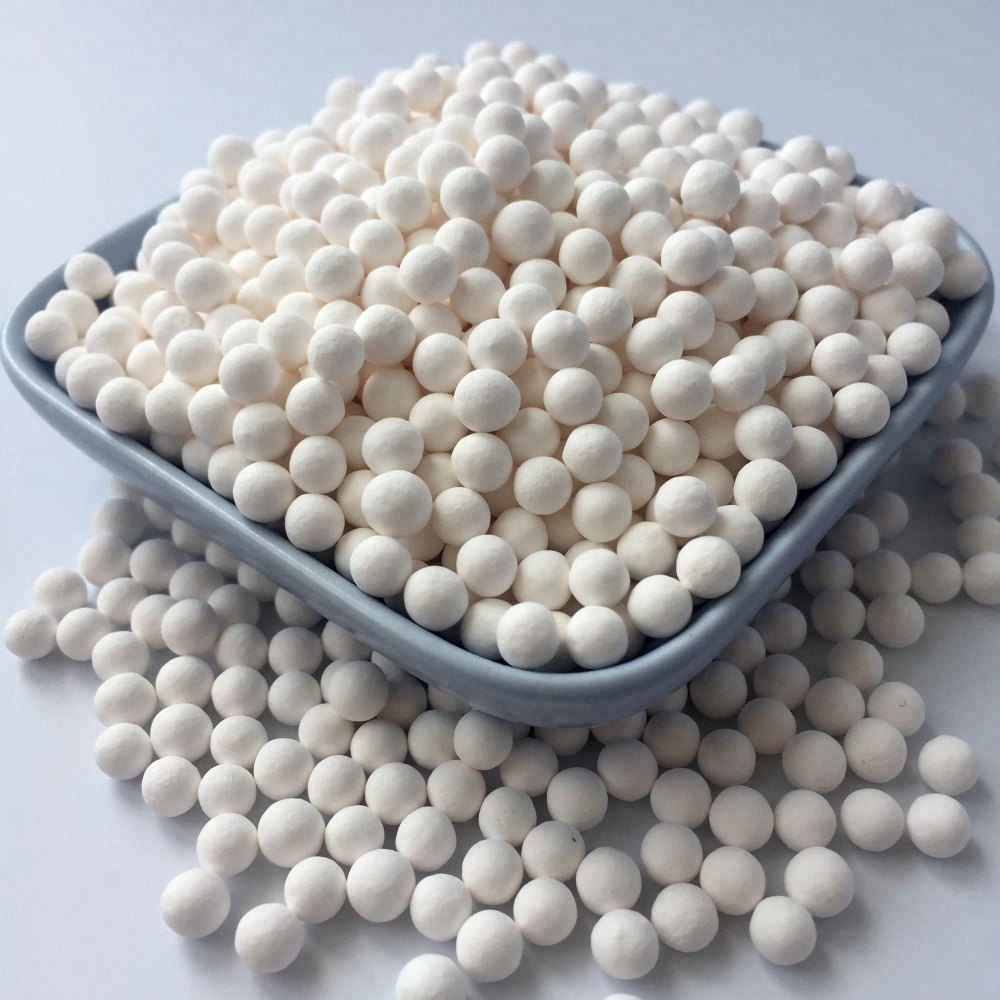

Compressed air systems generate a significant amount of condensate, much of which remains in a vapor state within

the airstream. Desiccant dryers that are not maintained properly allow moisture to pass downstream. In addition to poor maintenance, if low quality activated alumina is used, there is a higher level of dusting and less condensate adsorption capability. This contaminated air traveling downstream can dramatically reduce the performance and service life of process equipment and point-of-use tools.

Compressed air systems generate a significant amount of condensate, much of which remains in a vapor state within

the airstream. Desiccant dryers that are not maintained properly allow moisture to pass downstream. In addition to poor maintenance, if low quality activated alumina is used, there is a higher level of dusting and less condensate adsorption capability. This contaminated air traveling downstream can dramatically reduce the performance and service life of process equipment and point-of-use tools.

Using high-quality activated alumina desiccant from Ingersoll Rand gives you better control of system conditions like pressure, temperature and moisture levels. It also helps to achieve low pressure dew point temperature ranges from -40°F to -100°F (-40°C to -70°C)—ensuring the highest level of clean and dry air possible, while maximizing equipment performance and service life.

With a solid reputation built on years of expertise, SAJ serves as a trusted partner to professionals in the aviation, marine, and oil & gas industries, offering unmatched quality and service.

Our extensive product line includes innovative solutions like durable nomex suits, high-quality flight jackets, reliable life rafts, essential survival vests, advanced rescue harnesses, precision parachutes, and state-of-the-art aviation helmets, among other crucial search & rescue tools.

D-12-2, Menara Mitraland, 13A, Jalan PJU 5/1, Kota Damansara, 47810, Petaling Jaya, Selangor, Malaysia

T: +(6)03 7610 0100 | M: +(6)010 325 8855

F: +(6)03 7610 0200

E: info@seriaero.com

Terms of Use

Privacy Policy

PDPA

With a solid reputation built on years of expertise, SAJ serves as a trusted partner to professionals in the aviation, marine, and oil & gas industries, offering unmatched quality and service.

Our extensive product line includes innovative solutions like durable nomex suits, high-quality flight jackets, reliable life rafts, essential survival vests, advanced rescue harnesses, precision parachutes, and state-of-the-art aviation helmets, among other crucial search & rescue tools.

D-12-2, Menara Mitraland, 13A, Jalan PJU 5/1, Kota Damansara, 47810, Petaling Jaya, Selangor, Malaysia

T: +(6)03 7610 0100 | M: +(6)010 325 8855

F: +(6)03 7610 0200

E: info@seriaero.com

Disclaimer

Terms of Use

Privacy Policy

PDPA

© Copyright © 2024 Seri Aero Jaya Sdn Bhd (61839-k) All Rights Reserved.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.